GENERAL CHARACTERISTICS OF DRY SEPARATION METHODS - Basic advantages

The comprehensive method of dry separation of raw materials is an innovative and revolutionary solution on a global scale. It allows efficient, cheap and effective exploitation of natural resources and the recycling of mineral waste and/or mineral waste deposits.

Water access is not necessary

This technology doesn't need water, which allows to use it in the areas, where water is hard to achieve. Besides, non-water production process is ecological solution.

Fast implementation

The first production run is possible within 3 – 12 months.

No need to own or build costly infrastructure / facilities

You do not need to have your own infrastructure or to bulid one (like roads, water-sewage system, buildings and other facilities).

Modular construction and comprehensive mobility

The ability to adapt the solution to the size of the deposits. Thanks to the modular construction, it is possible to use a comprehensive mobile solution, e.g. on trucks. The construction of devices allows to transport them easily and use again in a new location.

Effective recycling and processing of excavations and waste deposits

The method is effective for the recycling and processing of excavations, heaps and waste deposits coming from industrial plants and factories.

High resistance to pollution

The technology is resistant to such pollution as clay, limestone, caries, plastics, sticky impurities, sludge and others.

Easy preparation of the raw material

The method does not require any costly preparation of raw materials (drying, grinding, etc.).

Efficiency

You can separate several raw materials during one process: gold, tantalum, cassiterite, ilmenite, trace elements, precious stones. The size of raw materials ranges from 0-200 mm. This method is also effective in case of small physical-chemical differences within the raw material.

No climate restrictions and limitations

This method works equally well in desert areas, wet equatorial conditions and temperate climates.

Safe handling

There is no dust in the treatment process, so the work is not harmful and the risks of illness, including so-called "Desert fever" and pneumoconiosis, are eliminated.

NON-WATER TECHNOLOGIES – FIELDS OF APPLICATION FOR DRY SEPARATION TECHNOLOGY

NATURAL RESOURCES

-bound form (e.g. metal ore),

– quantities that exclude their mass (bulk) exploitation – due to low quantity or profitability

INDUSTRIAL RESOURCES

– generated by industrial activities (furnace dusts; fluidized and flotation dusts, metallurgical slurry and sludge, other post-production waste)

MINERALS

– natural deposits of high concentration, allowing mass industrial extraction, e.g. coal, lignite, kaolin, salt, dolomite

APPROACH - ACTIVITIES:

RESULTS:

DESCRIPTION AND GENERAL CHARACTERISTICS OF SELECTED TECHNOLOGIES.

Both, the scope of research and the offered solutions are the result of several developed technological solutions, described briefly below.

I. Comprehensive „dry technology” for mining industry in the selective processing of rare non-ferrous ores and precious elements.

It includes the development of innovative solutions for the exploitation of mineral resources in opencast mining, both in the extraction process and in the enrichment process – without water.

Technological solutions related to minerals extraction enable highly efficient selection of ores with minimum investment costs.

By this technology, in parallel with obtaining basic products (rare elements concentrates and noble metals) the Customer achieves additional materials like clay, sand, etc.

Designed extraction device assures very beneficial technical and economic effects – it allows to exploit low-potential deposits, also in difficult and variable geological conditions, in distant areas without transport and energy infrastructure.

It minimizes the impact on the environment (fast reclamation of production sites without the need for water).

This technology has been tested at the industrial production level, receiving positive reviews from leading experts and organizations.

It can be used in cases where applying the traditional technologies is unprofitable or impossible due to lack of infrastructure (e.g. desert and mountain regions of Africa, Asia, Australia, Latin America) ordue to environmental reasons (e.g. beaches of India and Australia).

II. Technology and devices for the removal of dry clay and mud surrounding ore deposits (manganese ores, metal ores, precious stones etc.).

This solution allows to obtain an enriched raw material already at the initial stage of extraction. Prior to the main process, the raw material is processed by separating and removing the elements accompanying the ore (clay, sludge and sand) and extracting the ore without using water (rinsing).

The installation using this technology consumes only electricity and can be applied directly at the site of exploatation (extraction). It can cooperate with various types of specialized mining and transport equipment, creating an integrated system.

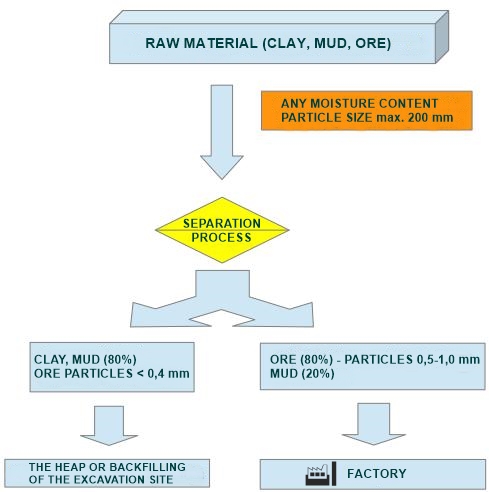

The device separates the excavated raw material as follows:

This solution supports existing technologies to improve the technical and economic indexes, especially when obtaining the raw materials is connected with high financial costs (manganese ore and iron ore deposits) or when the sludge contains a small amount of valuable ingredients (precious stones, rare and precious metals ), and also when the deposits are located away from water.

III. Cleaning and processing of metallurgical sludge.

Each metallurgical plant, during the smelting and processing of metals, generates a certain amount of waste that is used only partially. The sludge contains very valuable raw materials, however, the use of these materials is very limited – the reason is, among others, their pollution by harmful non-ferrous metals (mainly zinc and lead) and also unstable particle size distribution,

The developed solution allows to clean the particles forming sludge, their classification and division.

The basis of this technology is ultrasonic cleansing and disintegration of the material, followed by gravitational and magnetic separation. This technology exceptionally uses water as a liquid medium (water in circulation).

The processing of the raw material results in obtaining a number of commercial products: superconcentrate of iron (concentrated at 68-70%), coal, zinc concentrate and fillers for civil engineering.

Tests and trials confirmed that the technology of partitioning and surface treatment of raw particles, together with magnetic and gravitational separation, significantly enhances the efficiency of major processes of enrichment and processing of raw materials (iron ores, nonferrous metal ores) and significantly intensifies hydrometallurgical processes.

IV. Comprehensive processing of fly ashes in power plants.

We developed a comprehensive „dry technology”, combining the efficiency of gravitational separation, magnetic separation and electroseparation, which ensures full utilization of the input raw material. The uniqueness of this technology is the fact that it uses a raw material base in both pulverized and fluidized boilers.

Through this specific fly ash recycling you can receive the following products:

- pozzolana – an additive for Portland cement (according to standard composition and properties, it can replace up to 60% of cement)

- concentrate containing iron (raw material for the production of iron alloys),

- unburnt coal (degree of concentration allows to reuse it);

- microsphere.

Moreover, this technology can be used to obtain concentrates of rare minerals and trace elements in quantities suitable for further processed. The technology has been tested and implemented in several thermal power plants worldwide.

V. Separation technology (dry gravity) of raw salt (halite).

The essence of this technology is to disintegrate and separate the raw material. As a result of base mass processing, it is possible to remove (separation from salt) impurities and undesirable elements (sand, clay, soil and others) without the use of water. This increases the efficiency and quality of the extracted material. The basic requirement for efficient use of this technology is the zero moisture content of the feed, thus optimal location of the raw material processing device.

Wastes of salt fractions in the form of clay can be used to produce briquettes-licks for animals (cows).

The installation in this technology is characterized by compact design, low weight and low power consumption. It can work directly at the mining site (underground) or on the surface (it is possible to combine with traditional pre-treatment technology).

This technology has been successfully tested in rock salt mines and potassium salt mines.

Ekonomiczny efekt zastosowania tej technologii: The economic effect of applying this technology:

- optimization of mining works,

- reduction of product losses during extraction and processing – lower operating costs,

- improved salt quality,

- development of production from by-products (e.g. briquettes-licks),

- a rapid decrease of dust pollution in the mine, thus a significant improvement in working conditions and reducing the associated costs.

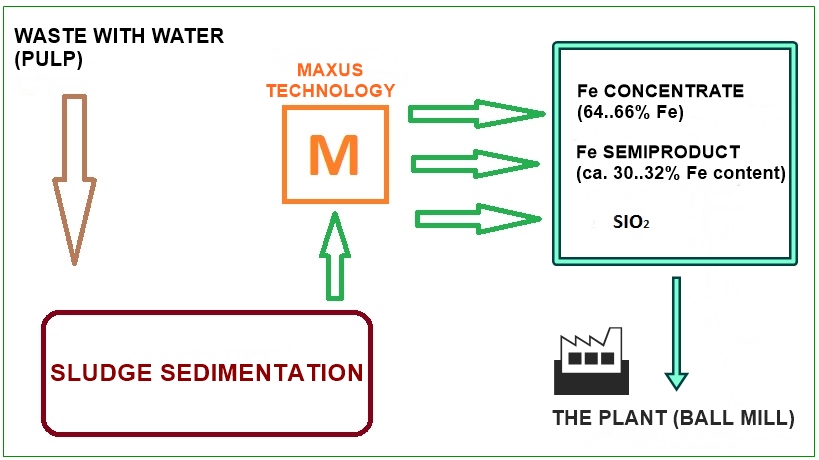

VI. Dry technology for complex processing of iron ore mining waste.

This solution is effective for the processing of raw materials with low initial iron content (Fe<10%) through dry magnetic and gravitational separation.

As a result of processing, the following products are obtained:

- iron ore concentrate (concentration of Fe ≈ 64 – 66%, with high recovery rate);

- industrial semiproduct (Fe content is so high that allows to redirect the semiproduct to the main enrichment process in the plant);

- mineral sands for construction and powder for asphalt mixtures.

An example of use is illustrated by figure below:

Comprehensive and modular construction of the installation operating in this technology allows to minimize capital expenditure and locate the processing near the source of raw material.

The described recycling is also possible for uranium ores, non-ferrous metal ores and heavy metal ores.

VII. Technology of initial magnetic/gravitational enrichment of ores.

The developed technological solution and the designed installation enables preparation of non-ferrous and heavy metals’ ores for their enrichment – by fine grinding, milling and water-free classification. At the same time, raw materials are initially enriched with magnetic and gravitational methods.

The installation operating in this technology implements the combined effect of magnetic force, gravity and centrifugal force (inertia effect), segregation by vibrations and size classification.

Eliminating water from the treatment process allows for significant reduction of infrastructure costs (which would be needed for processing in a standard way).

Particular technologies and devices are successfully used in initial enrichment operations in iron ore extraction and processing plants, as well as on the post-production raw material processing lines (ore waste sludge, metallurgical slags, solid fuel slags from thermal power plants).

VIII. Technology of complex processing of metallurgical slags.

These are non-standard technical solutions to ensure the comprehensive processing and most complete use of slag from various steel industries (metallurgical furnaces, ferro-alloys and non-ferrous metallurgy).

Comprehensive system of raw material processing based on selection together with magnetic and gravitational separation allows to obtain many commercial products:.

- Metal concentrates with different characteristics (magnetic and non-magnetic compounds, non-ferrous metals containing ferrous) and metal oxides.

- Sand aggregates – These products, because of their selective grinding, separation and quality classification, have high performance properties (appreciated utility properties ) and are used as fillers in construction industry.

- Mineral powders – active mineral components and fractionated powders obtained from slag refining, which makes them suitable as additives for Portland cements, active fillers for asphalt mixtures and the base for construction non-clinker binders.

The production of non-clinker construction adhesives and construction products based on them can be an additional and highly profitable activity when the bulk slag reserves are available (landfills and slag heaps).

IX. Limestone processing technology.

Significant amounts of limestone are used in the mining and metallurgical processing. The developed technology allows to use this raw material entirely for the following products:

- lime briquettes – such processed binder is stable and repetitive in terms of chemical composition and physico-mechanical properties

- fillers – fractionated sand

- calcium binder – non-clinker binder (clinker free)

- fillers for civil engineering and binders for the construction products (airbricks, cell blocks, paving stones, drainage elements etc.).

- fertilizers used in agriculture.

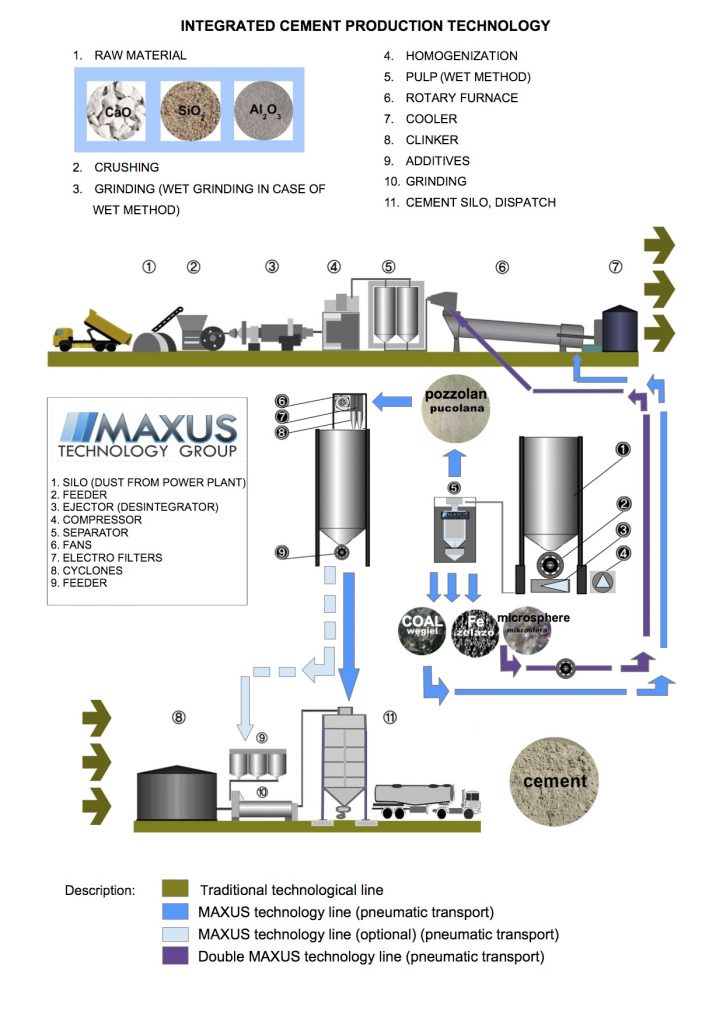

X. INTEGRATED CEMENT PRODUCTION TECHNOLOGY.